|

#2

6th January 2017, 04:28 PM

| |||

| |||

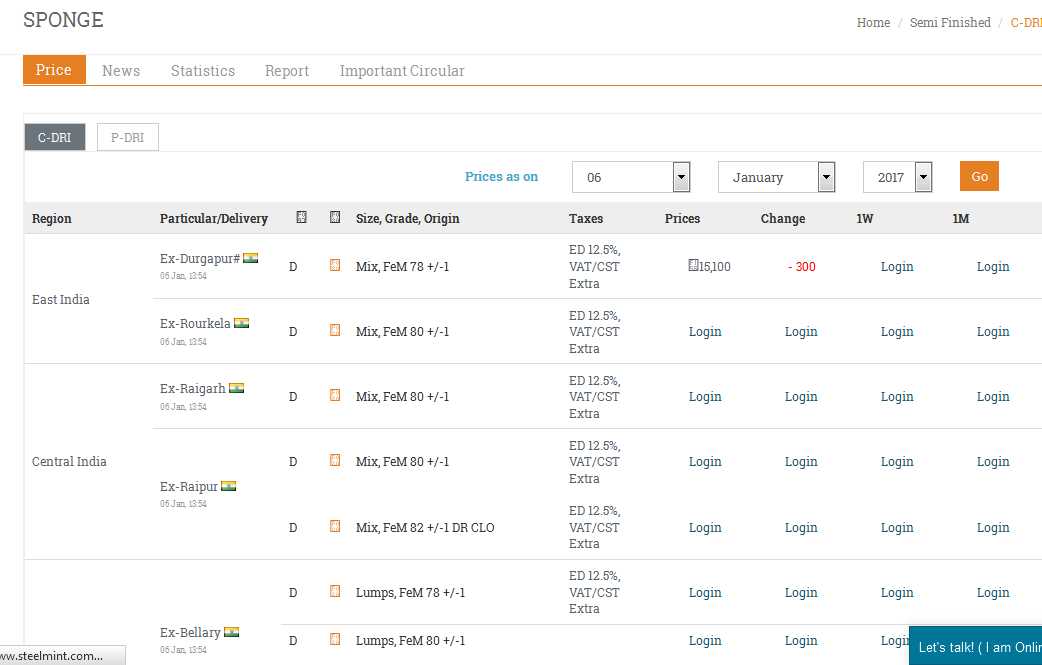

| Re: Sponge Iron Prices In India

Sponge iron also called Direct-reduced iron (DRI), It is produced from the direct reduction of iron ore (in the form of lumps, pellets or fines) to iron by a reducing gas produced from natural gas or coal. Few ores are suitable for direct reduction. India is the world’s largest producer of direct-reduced iron, a vital constituent of the steel industry. Many other countries use variants of the process, so providing iron for local engineering industries. As you asking here I am telling about Sponge Iron Prices In India Sponge Iron Prices In India  Factors that help make DRI economical: Direct-reduced iron has about the same iron content as pig iron, typically 90–94% total iron (depending on the quality of the raw ore) as opposed to about 93% for molten pig iron, so it is an excellent feedstock for the electric furnaces used by mini mills, allowing them to use lower grades of scrap for the rest of the charge or to produce higher grades of steel. Hot-briquetted iron (HBI) is a compacted form of DRI designed for ease of shipping, handling, and storage. Hot direct reduced iron (HDRI) is iron not cooled before discharge from the reduction furnace, that is immediately transported to a waiting electric arc furnace and charged, thereby saving energy. The direct reduction process uses pelletized iron ore or natural "lump" ore. One exception is the fluidized bed process which requires sized iron ore particles. The direct reduction process can use natural gas contaminated with inert gases, avoiding the need to remove these gases for other use. However, any inert gas contamination of the reducing gas lowers the effect (quality) of that gas stream and the thermal efficiency of the process. Supplies of powdered ore and raw natural gas are both available in areas such as Northern Australia, avoiding transport costs for the gas. In most cases the DRI plant is located near natural gas source as it is more cost effective to ship the ore rather than the gas. this method produces 97% pure iron. |